RECYCLED RICE HUSK FIBER

Leftover Rice Husk Gets New Life:

South and Southeast Asia account for over 90% of the world’s rice production.

Rice husk is a major by-product of the rice-milling industry and is abundantly available.

However, rice husks have been considered a waste which causes disposal problems.

Rice husk has been recognized as a potential source of energy. Researchers have developed the gasification of rice husks to run purely on waste instead of edible raw materials — –transforming waste into valuable material.

Details

Environment protection and clean biomass energy is the sole renewable energy that can be converted to clean fuel materials. Environment protection and clean biomass energy is the sole renewable energy that can be converted. Rice-Husk Gasification have abundant husk that can run their units on the power generated by using rice husk.

With the power generated by the use of rice husk, a large amount of carbonized rice husk waste is leftover after generating electric power.

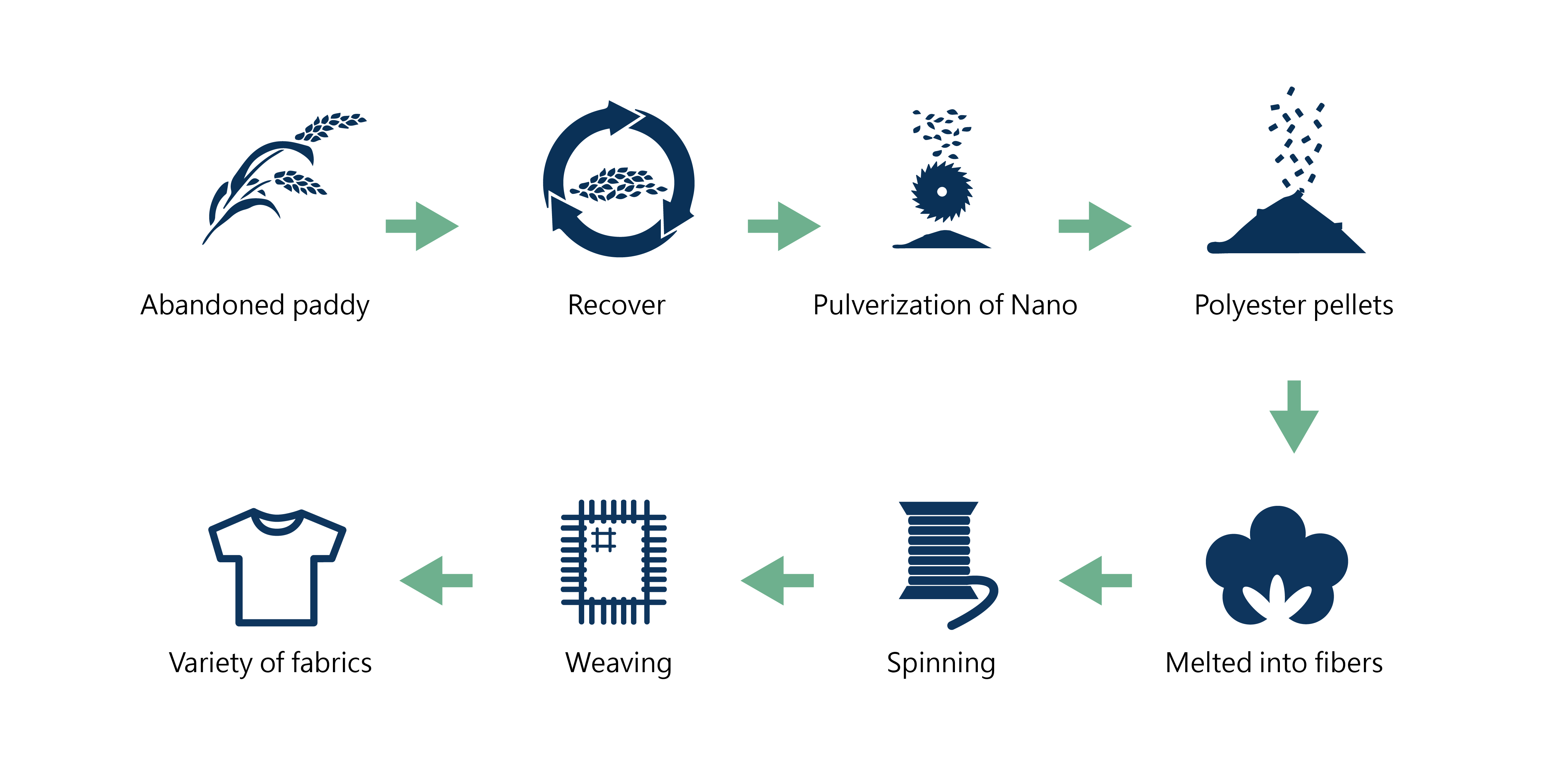

ECOMAX use trashes of carbonized rice husk taken from generate electric power as raw materials.

ECOMAX makes great efforts considering Eco Plus’s method to transform waste into valuable material.

ECOMAX adds carbonized rice husk to change it into yarn.

The recycled rice husk fiber is made from electricity generated leftover trash. By adding carbonized rice husk it changes into recycled PET fibre thus giving it a new life.

Procedure

Features

- Carbonized rice husk mainly composed of silicon dioxide and have absorbent, deodorant and far infrared function.

- Carbonized rice husk in a “delicate pores” does not only contain moisture and deodorant but also helps to adsorb toxic chemical substances.