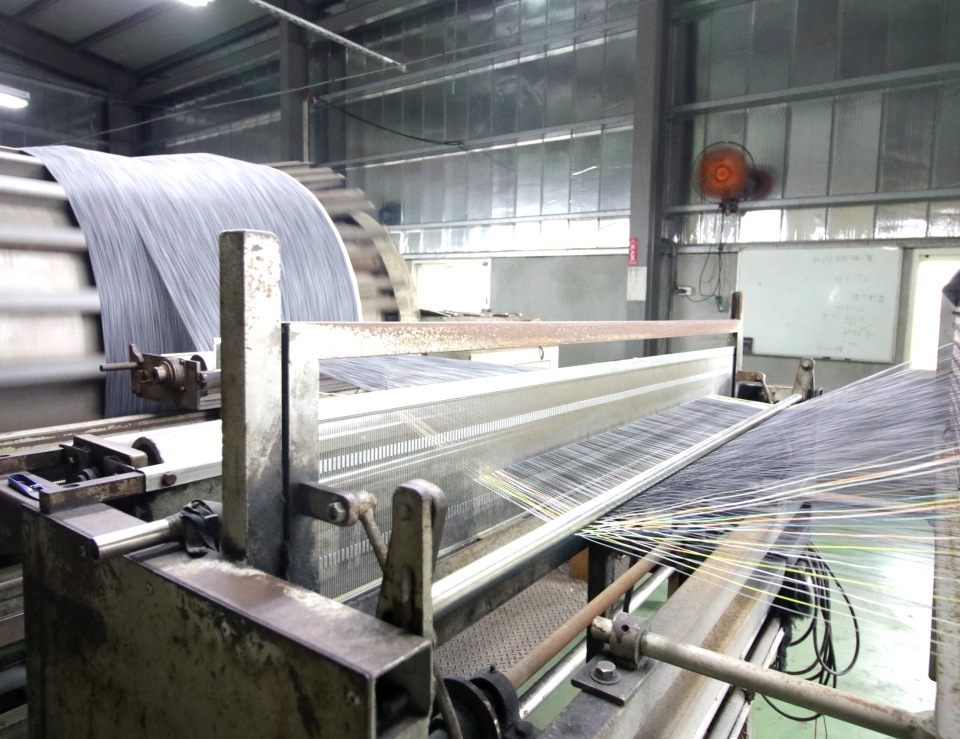

Back in the 1960s, it was the crucial period for Taiwan’s textile industry to flourish and promote the country’s economic take-off. Ecomax Textile located in Shenkang Township Chunghwa County was established at that time.

The current chairman, Mr. Mark recalled saying“I grew up in a textile factory and I am aware of the fabrics, yarns, and production process and after my father retires, I will take over his business.”

In 1993, Mark accidentally heard a speech from Cheng Yen, founder of the Tzu Chi foundation, saying “Use your applauding hands to do recycling”.This made Mark think about how to use his own textile background and devote his work to environmental protection. He once read in a magazine that American Apple brand jeans were made of five bottles but Taiwan didn’t have such technology and production capacity. Mark was deeply moved and made a commitment that he must succeed and make Taiwan use recycled bottles for clothing as well.